![]()

The services of WOLTZ GmbH for the design and supply of production plants for stone wool or rock wool include:

- Plant layout

- Plant engineering

- Turnkey construction

- Feasibility study and consultancy services

- Project planning, design and evaluation

- Procurement and commissioning

- Installation and erection of equipment

We offer on-site training on our reference partners' premises and are prepared to commission your stone or rock wool plant. Depending on our customers' requirements, we either assist in the erection of the equipment or carry out the complete assembly and erection of the plant.

Our supplies include e. g.:

- Equipment for quarry (e. g. front loader, dredger, trucks, trailors)

- Raw material charging system and batch house (e. g. for basalt, limestone, dolomite)

- Coke or gas fired Cupola furnaces (2,5 - 8 to/h) or gas-fired furnaces (1,5 - 5 to/h)

- Spinner / fiberizing technique (1,5 - 8 to per h and per spinner)

- Collection chamber

- Pendelum

- Curing oven

- Product Finishing

- Packaging

- Auxiliaries

- Electric Control

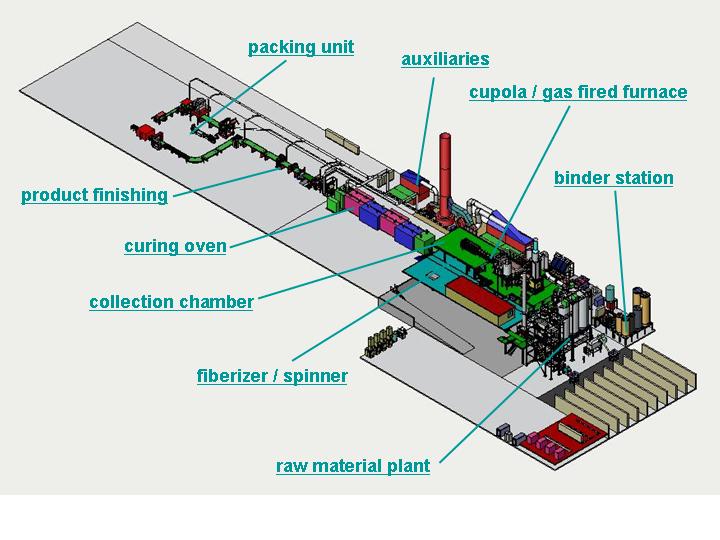

principle layout stone wool plant with gas fired furnace

stone wool product with inorganic binder

The

produced stone wool boards can be processed to sandwich panels. For detailed

information please click here:

Production

line for sandwich panels

Pipe wrap machines